energy & savings

energy & savings

compared to classical warehouse applications such as conveyor belts or robots, the fluid technology has tremendous advantages

- a mover can be used in any size or format – from a cup of tea to large sea containers

- a mover needs some new wheels from time to time – no further maintenance is needed

- a mover has the energy requirement of a classic light bulb – only while moving, of course

sustainability

sustainability

robots and other AGVs require maintenance. they need to be recharged. they need to be repaired. they are limited to a specific range of formats.

- our movers have no mechanical parts apart from the wheels in use – nearly no maintenance is needed

- our movers do not need batteries – the only power device is built-in in the floor (“stator”)

- our movers can handle multiple loads of any format – if not alone then as a swarm

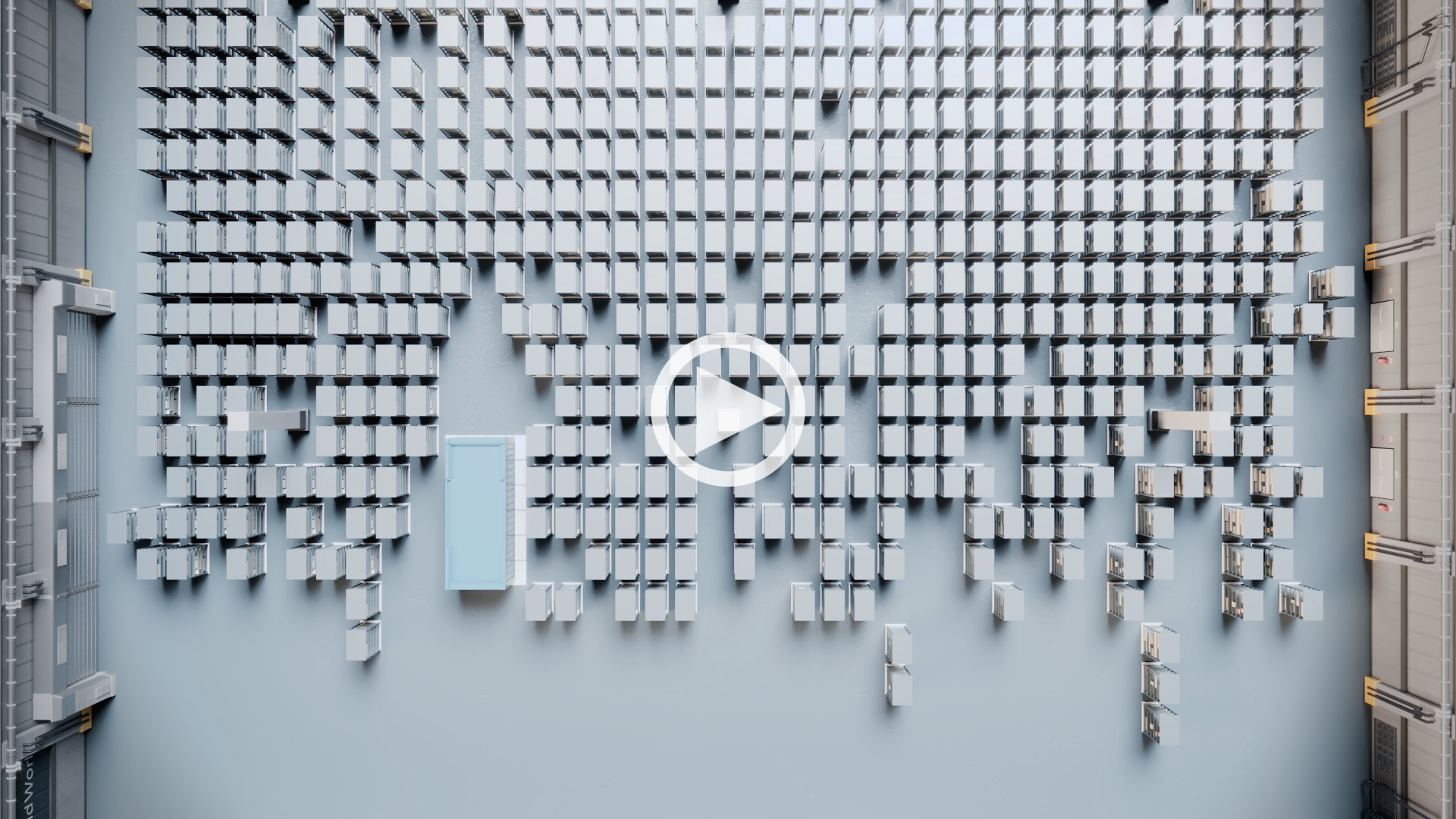

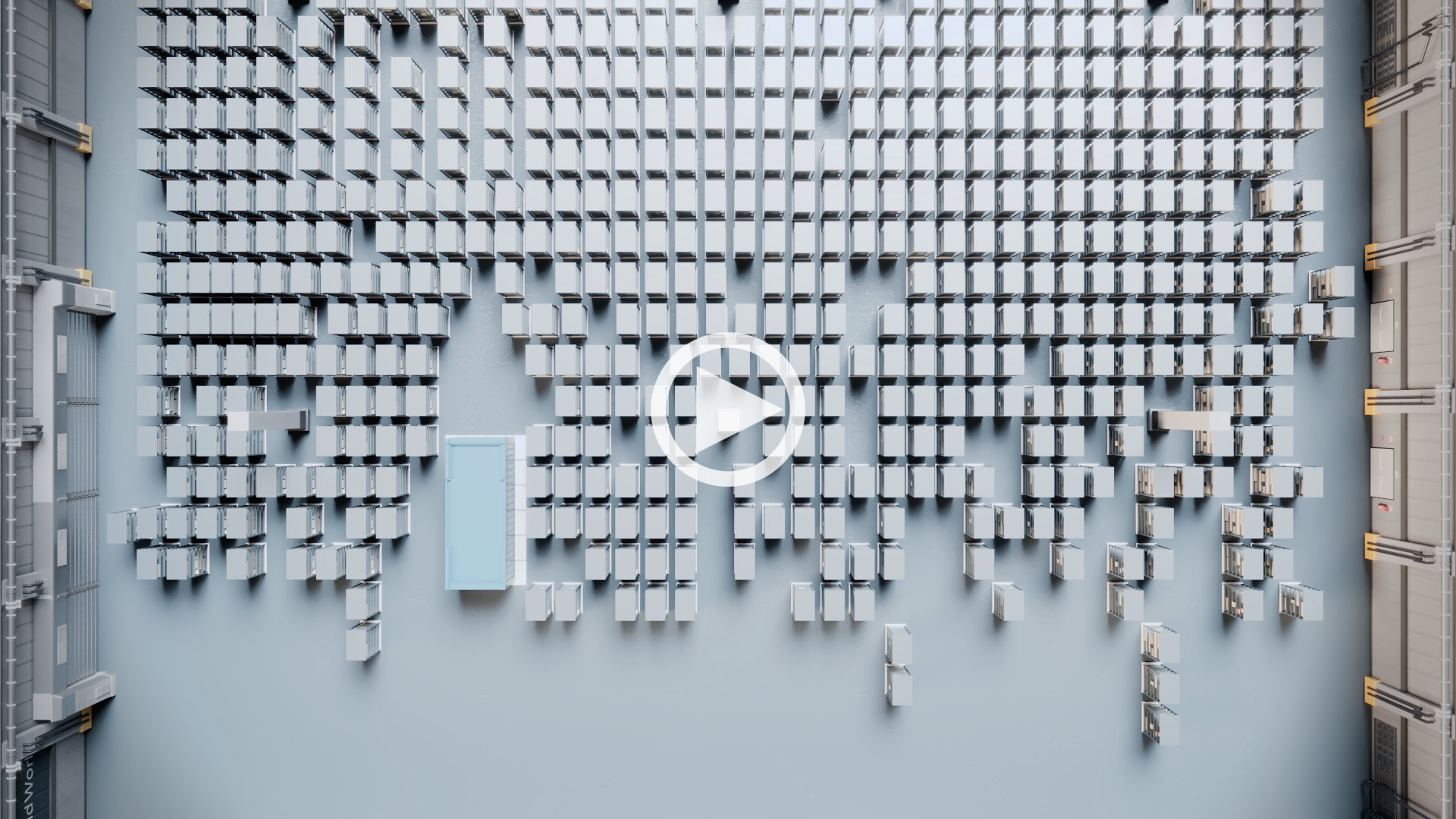

parallelism

parallelism

the success of a warehouse depends on the turnover performance and the costs per pick.

- as the “motor” is built into the floor, the movers can all move everywhere

- the software orchestrates the simultaneous movement of all required movers – at once

- the fluid technology can be seamlessly integrated into existing environments and also adopt to any format needed

spatial efficiency

spatial efficiency

traditional warehouses consume a lot of space. even robotic warehouses still need aisles among each shelf.

- fluid warehouses allow the highest density of storage space

- artificial intelligence optimizes material flow

- as each object can be moved at any time, picking times are significantly reduced

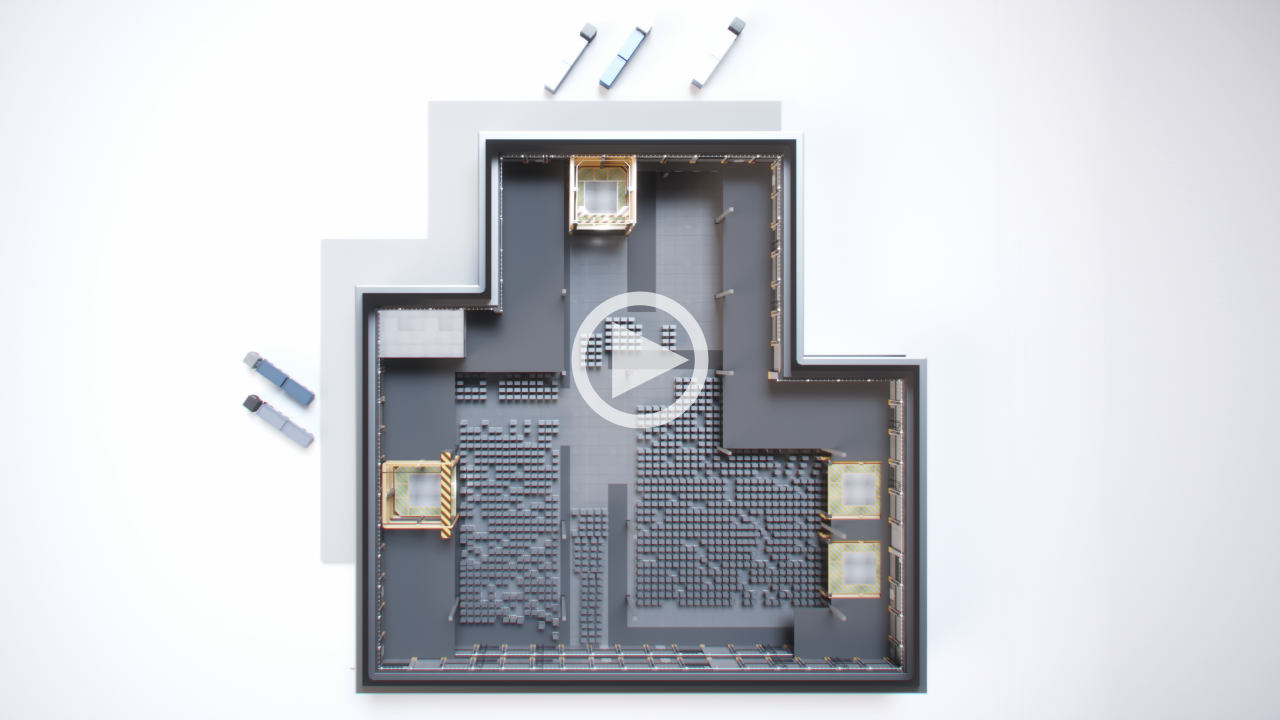

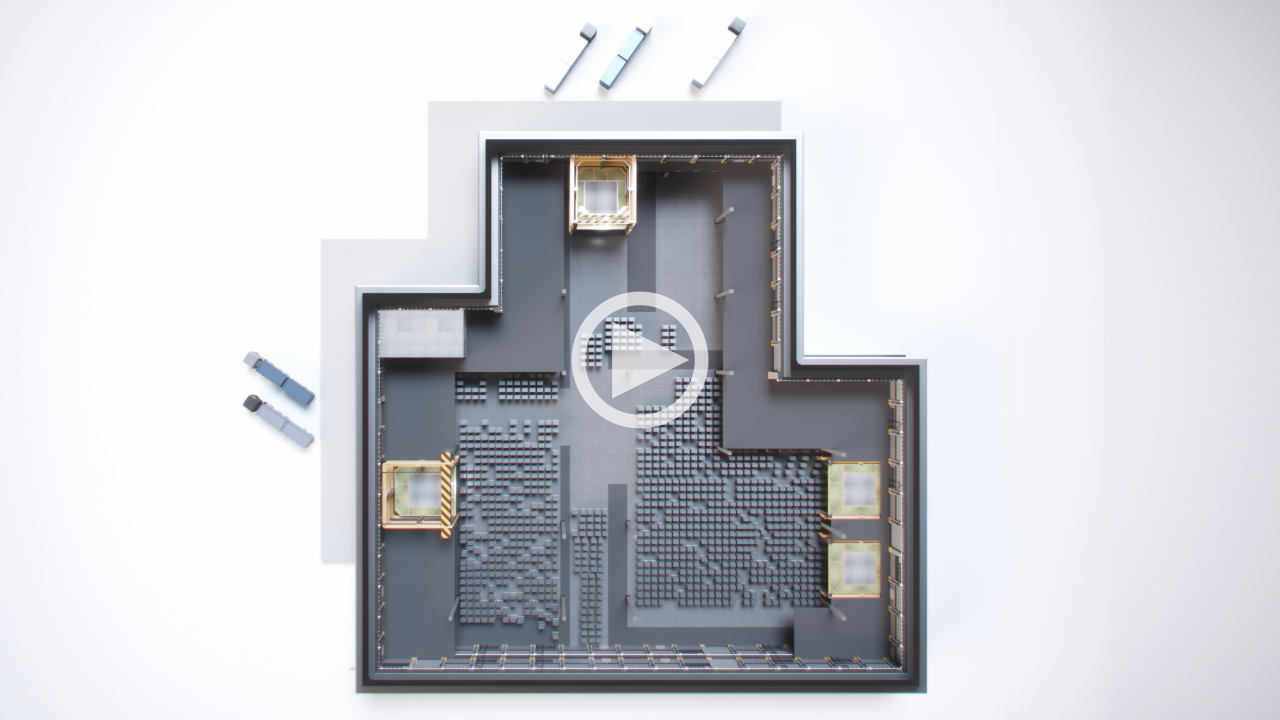

adaptability

adaptability

the fluid technology is basically a simple technology

- a parallel integration into an existing environment (traditional or robot warehouses) is an option

- an integration into an existing building is also an option

- the adaptation of the new technology can be implemented step by step